Our People

Your Moulds

Your Moulds

Since 1974 we have been designing and manufacturing molds and technological solutions for rubber and elastomeric gaskets and seals:

such as O-Rings, frames, washers, bellows, sleeves, membranes and a variety of items based on drawings for a wide range of applications.

VALUES

Credibility is our key value. We believe in the importance of establishing long-lasting collaborations with our national and international clients. Straightforward and effective communication, quality and constant innovation represent our professional standards.

VISION

We want to support our clients in realizing outstanding products that improve daily life and become key values for the entire community.

MISSION

We devise high-quality and long-lasting solutions for the molding issues faced by our clients, helping them overcome daily challenges thanks to our team’s experience, engagement and constant training as well as the technological innovation offered by our machines.

OUR WORK

We listen to our clients to understand their needs right from the critical planning stage, working side by side to find the best solution: from compound waste to part ejection. We value both in-house safety and environment protection, analyzing and constantly improving established processes, training our collaborators and complying with European regulations for Safety and Environment Protection.

SINCE 1974

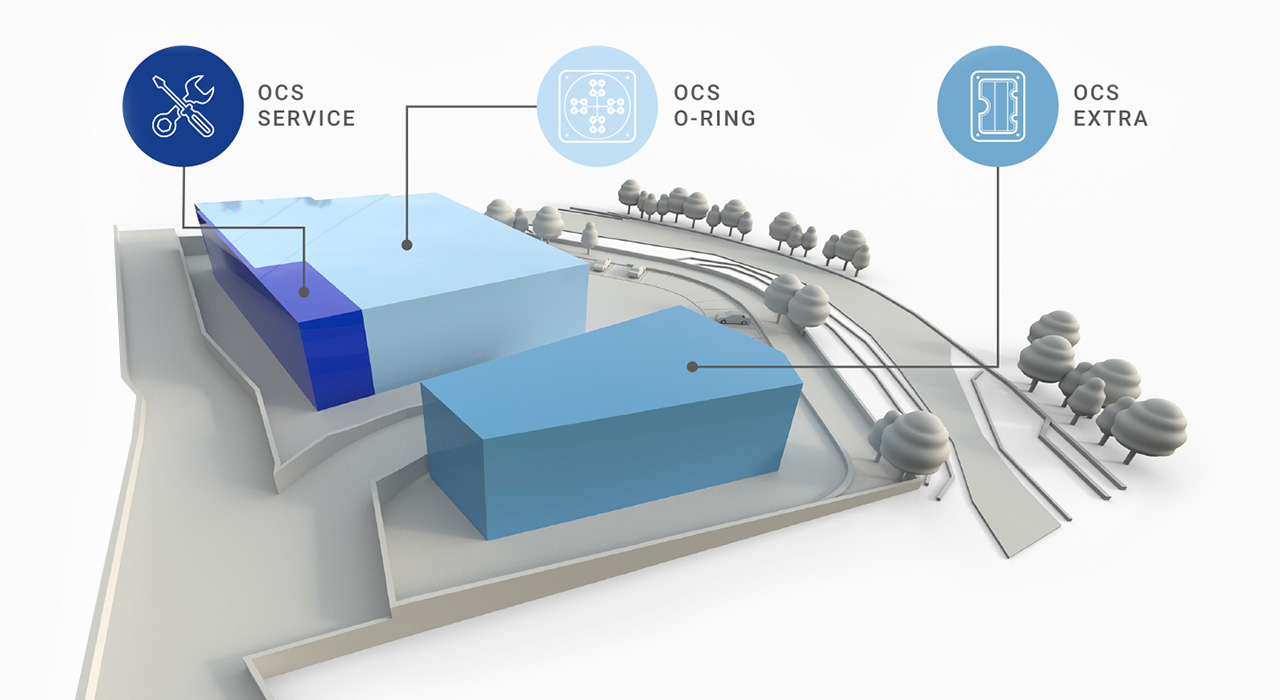

OCS O-Ring

This department designs and produces molds for O-rings and basic parts such as X-rings, V-rings, washers and frames.

OCS Extra

At OCS EXTRA we design and manufacture molds for technical items based on drawings that differ from standard O-rings and thus featuring multiple profiles and dimensions.

OCS Service

At OCS service we go way beyond manufacturing molds for rubber items. During the pre- and post-sale stage, our #ocsteam strives to find the best solution for our client.

WHY TO CHOOSE A COLD RUNNER BLOCK

Rubber moulding companies value the strategic role played by thermo-regulated blocks (CRBs) to enhance production cycles while reducing waste material.

Using a CRB means adopting an injection system able to keep the compound at pre-vulcanization temperature before injecting it near or into the mold.

This is made possible thanks to:

- insulation from the heat source;

- a controlled cooling system.

BENEFITS

- Better handling of difficult, highly accelerated compounds.

- Reduced risk of burning the compound.

- It is possible to inject the compound in several points of the mold.

- It is possible to use multiple-cavity molds.

- Reduction of non-conformities.

- Homogeneity and repeatability of molded items.

CRBs help you meet the needs of those major customers in the rubber industry who are no longer satisfied with the cheapest-cost-perpiece policy and who are now looking for:

- Manufacturers able to solve customers’ problems by anticipating needs and opportunities.

- Technical items and gaskets with increasingly higher performance to comply with the most demanding regulations.

- Reliable production timing.

FIELDS OF APPLICATION

Automotive

Aerospace

Oil and Gas

Medical

Robotics

Food and Beverages

Hydraulic

Electric and Household Appliances

OUR CLIENTS